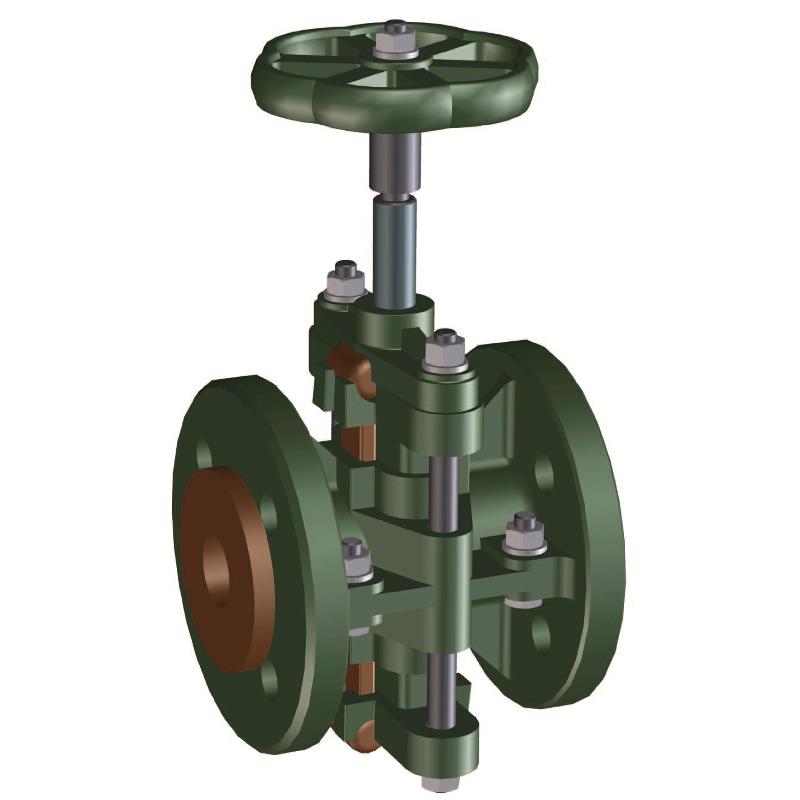

Pinch valves

Description

Hand and pneumatic operated pinch valves do not incorporate any stuffing box and are leaktight on all liquids, slurries, granular materials, powders, pastes, gases, acids etc.

Sleeve (internal rubber) is supported during opening and closing, and is easily replaceable without any special tools. The wide range of available elastomer materials enables an appropriate selection for each application and is a guarantee of perfect resistance to corrosion and abrasion.

Download catalouge: GO catalog Pinch Valves

PRODUCT FEATURES

Straight through way

Sized from ½” through 14”

Flanged valves in according to UNI PN 10 and ANSI/ASME 150#

Manual, pneumatic and electric operators

PERFORMANCE FEATURES

No loss of head

Faultless sealing on liquids, fluid suspensions, granulated materials, powders, sludge, gas, etc.

No packing

Quick and easy replacement of sleeve, no special tooling required

Sleeve supported during opening and closing: hence the possibility of under vacuum operation

No maintenance

Long durability

Threaded spindles and side tie rods in stainless steel

Cylinders in aluminium and specially treated cylinder springs on pneumatic models

Epoxy painted, valve bodies protected with an anti-acid varnish

BODY VALVE MATERIALS

Cast iron GG25/Cast iron A126

Spheroidal cast iron GGG40/Ductil iron ASTM A 395

Pure aluminium

Cast steel A 216 grade WCB

Cast steel A 352 grade LCB

316 Stainless steel ASTM A 351 grade CF3M

316 L Stainless steel ASTM A 351 grade CF8M

MATERIAL OF SLEEVES

Natural rubber

White natural rubber

Neoprene

EPDM

Viton

Butyl

Nitrile

Hypalon

Silicone

Neoprene/Silicon (mixed)

CERTIFICATES AVAILABLE

EN 10204 3.1.B

EN 10204 2.2

INSPECTION TESTS AVAILABLE BY

SGS GLOBAL TRADE SOLUTIONS

ITS INTERTEK TESTING SERVICES

BV BUREAU VERITAS